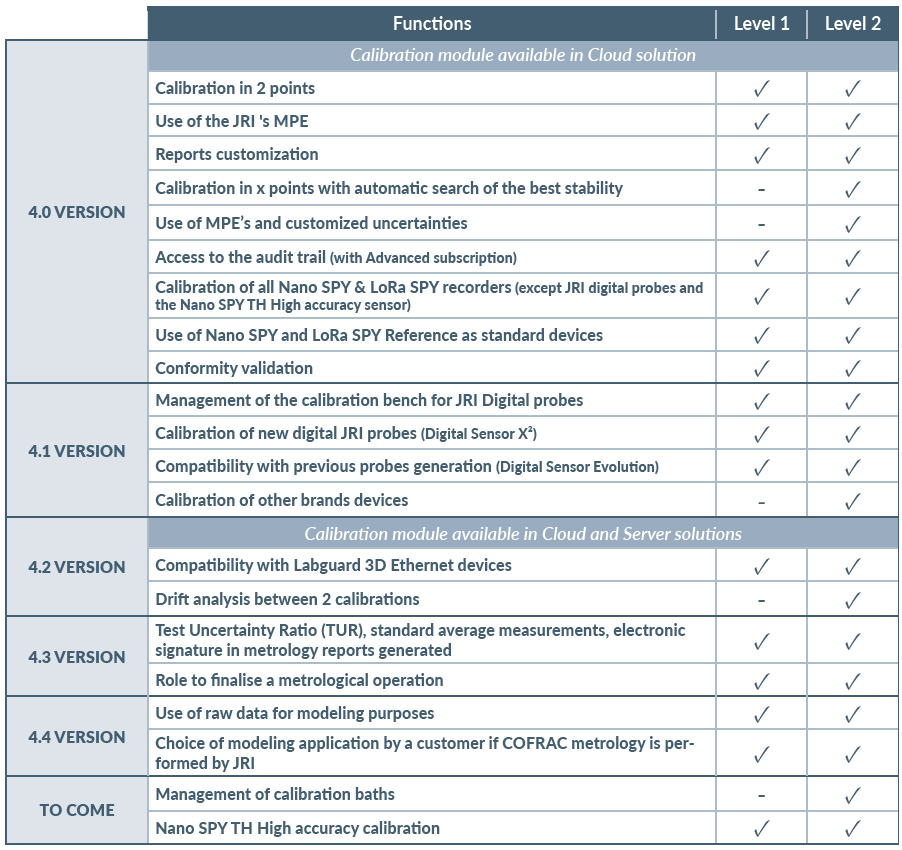

Description & levels

Main features

- Calibrate / check one or more measurement chains

- Adjust one or more measurement chains (modelization)

- Keep traceability of metrological operations of one or more measurement chains

- Send notifications to anticipate the renewal of metrological operations

- Drift analysis

- Calibration periodicity optimization

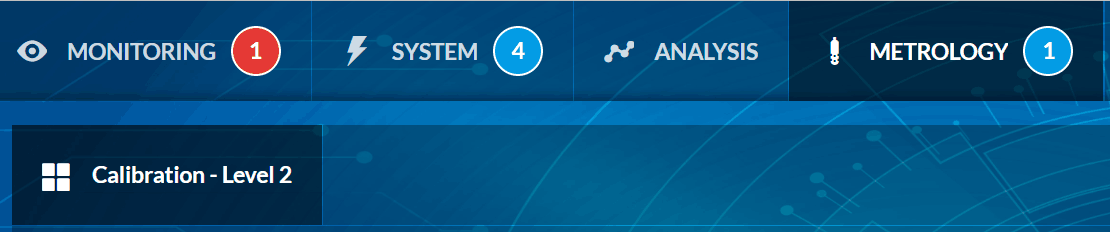

Levels

The level 1 or 2 of your MySirius Calibration module is indicated at the top of your Metrology dashboard.

Below are the functionalities available with each level:

Definitions

- Reference measuring system (Standard chain): Reference measurement chain (Example: Nano Reference)

- Environment : Equipment used to perform a metrological operation. Example: bath, oven, climatic chamber

- Program: Program of measurements of one or more points combining standards and adapted calibration mediums.

- MPE: Maximum Permissible Error

- Uncertainty components: Sources of measurement uncertainties

- Calibration Medium:

- Homogeneity

- Stability

- Measurement chain:

- Uncertainty of the reference chain

- Repeatability error

- Resolution of the reference chain

- Homogeneity of the reference chain

- Annual drift of the reference chain

- Stability of the reference chain

- Generic chains: Measurement chains other than the NOVA, NANO and LORA SPY ranges from JRI or LABGUARD 3D from Biomérieux.

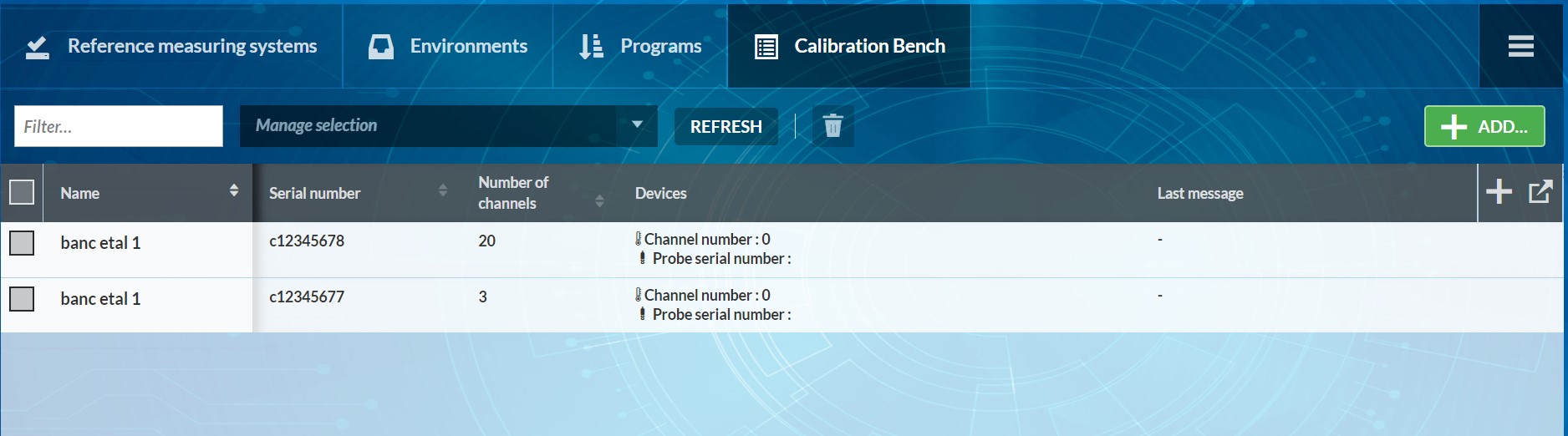

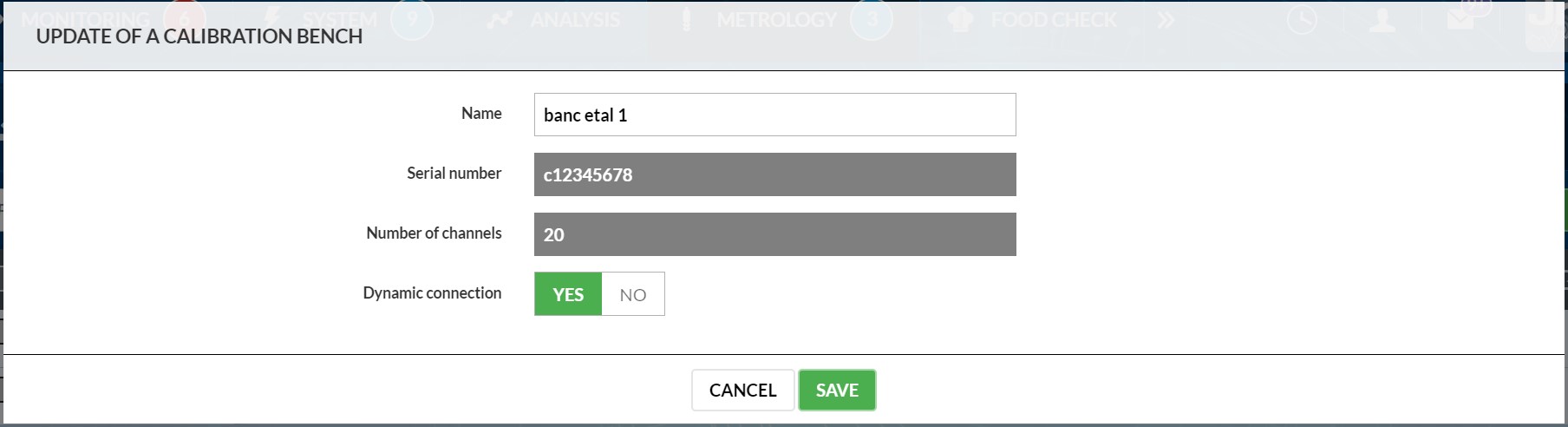

- Calibration bench: JRI device with 20 inputs allowing the calibration of JRI digital probes (Digital Sensor Evolution and Digital Sensor X²)

- Drift Analysis: Verification of the behavior of a measurement chain between two successive verifications or calibrations

- Periodicity optimization: optimization of the frequency of metrological operations on a measurement chain.

- TUR: Test Uncertainty Ratio. TUR = Acceptable Tolerance (TU [Upper Tolerance Limit] - TL [Lower Tolerance Limit]) / Calibration Uncertainty

Profiles

There are 2 profiles with specific rights on the Metrology module. These profiles can be applied to a user’s account (new or existing) from the ADMINISTRATION tab in the Profiles section.

- Metrologist Manager: All rights

- Metrologist: All rights except,

- Preferences management

- Metrological means management

- Deleting, Verifying and Signing metrological operations

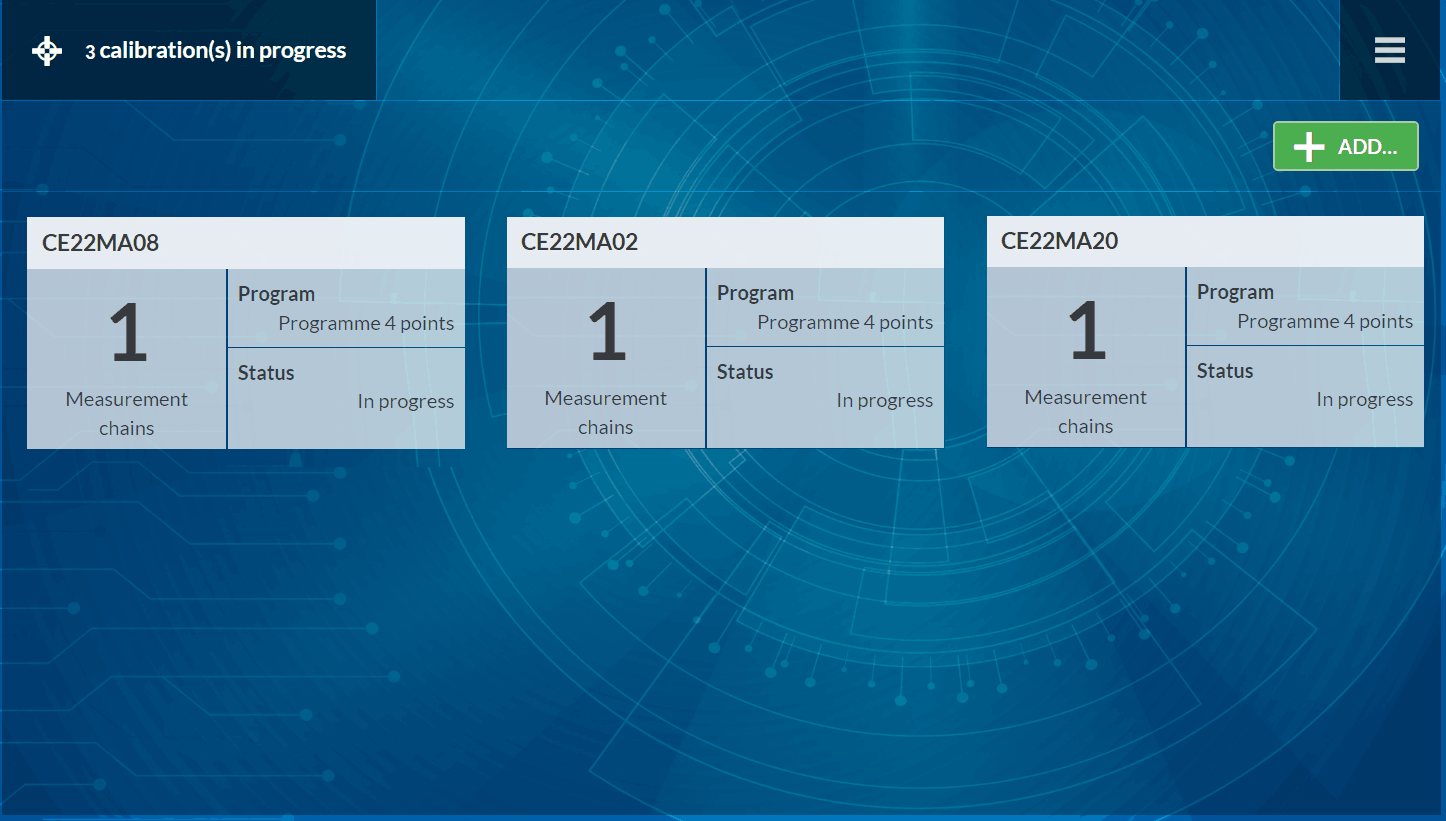

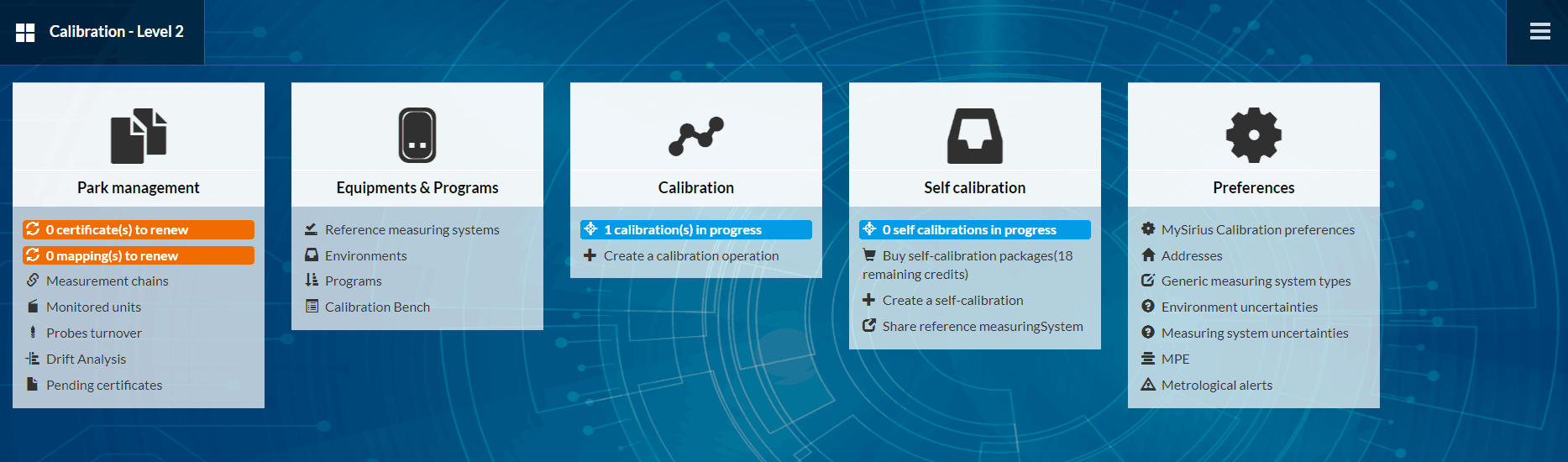

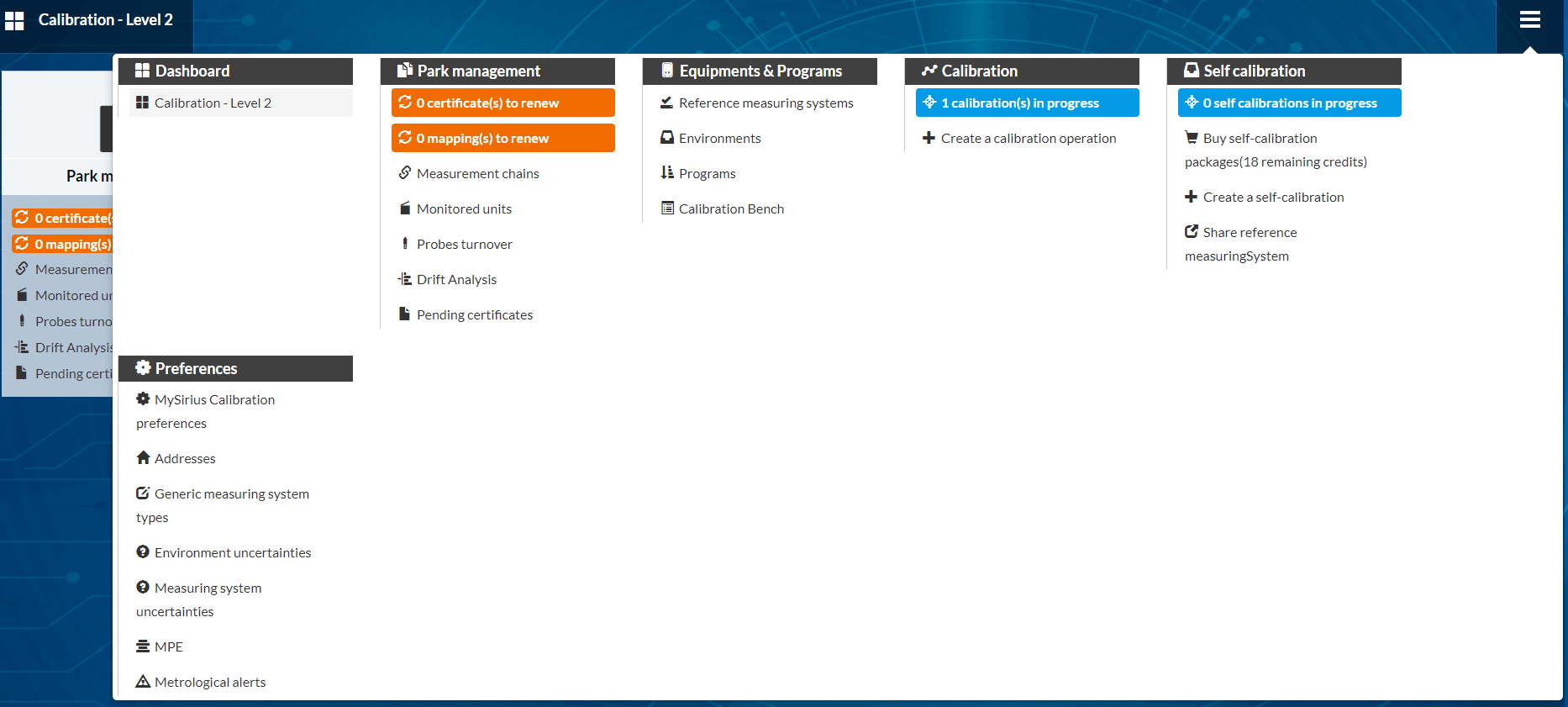

Dashboard

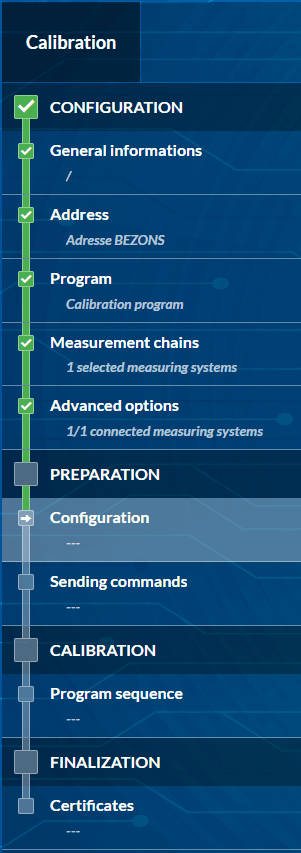

The home screen of the MySirius CALIBRATION module contains all the functionalities divided into 4 sections.

A quick access to the menu is possible by clicking on

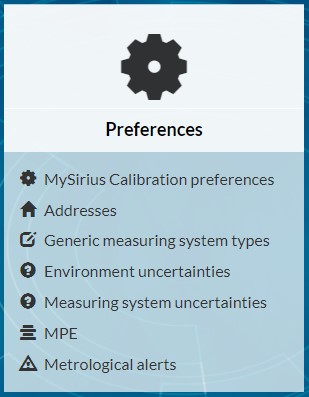

Preferences

Preferences defined in this section are applied to all the users of the Calibration Module.

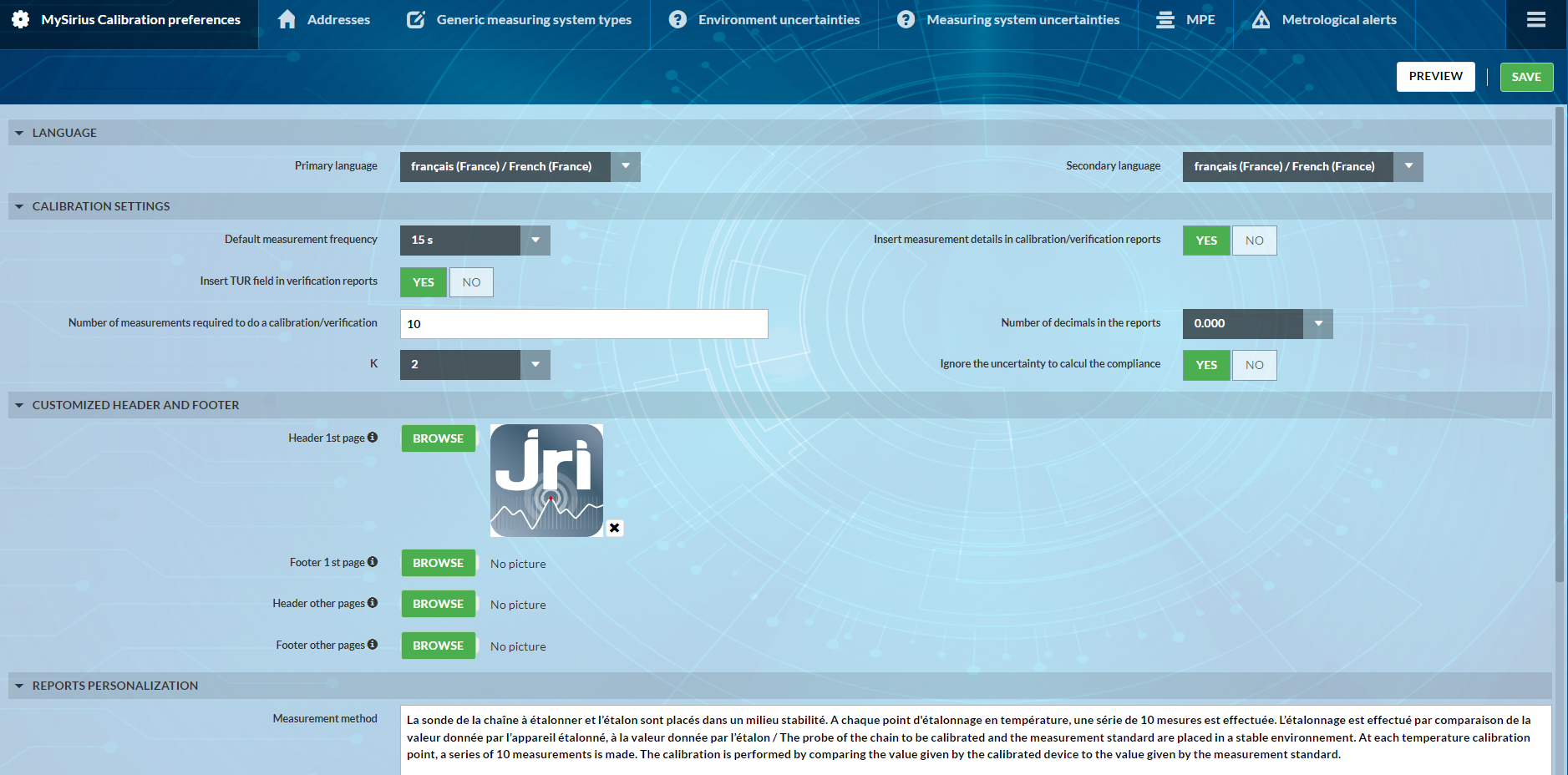

Mysirius Calibration Preferences

Customize your reports and set your language and calibration preferences. Use the “PREVIEW” button before saving your settings.

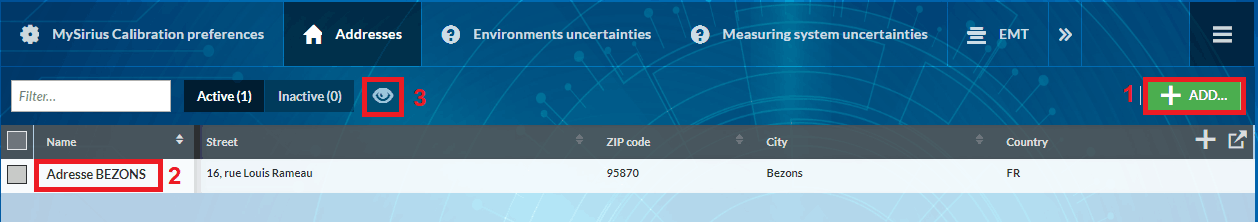

Addresses

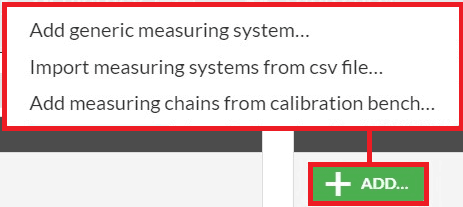

- Click on the “ADD” button to create a new address to be included in your reports.

- Click on an address to modify it.

- Use the

to hide a selected item, and the

to hide a selected item, and the  to show a selected item.

to show a selected item.

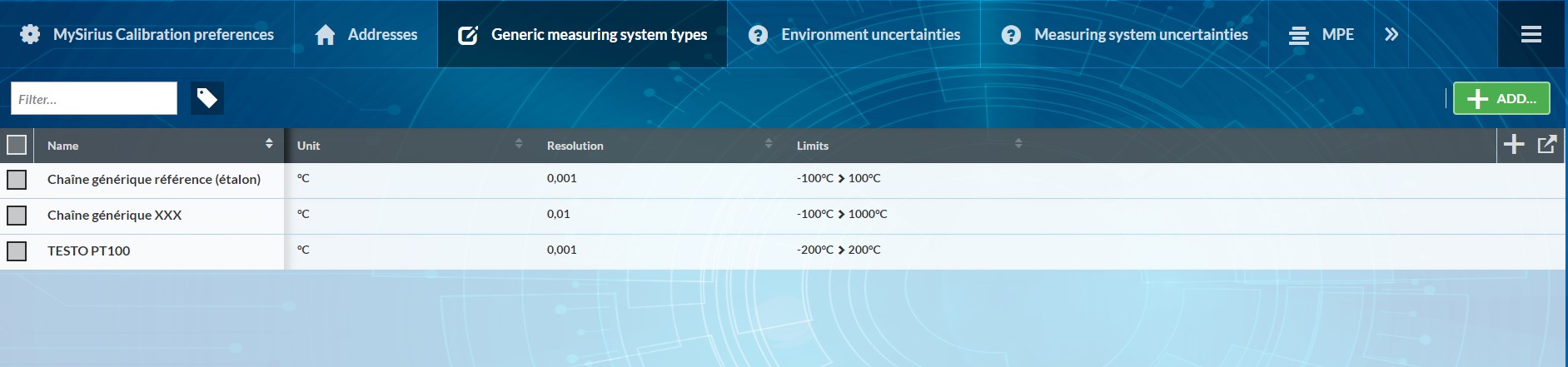

Generic measuring systems Types

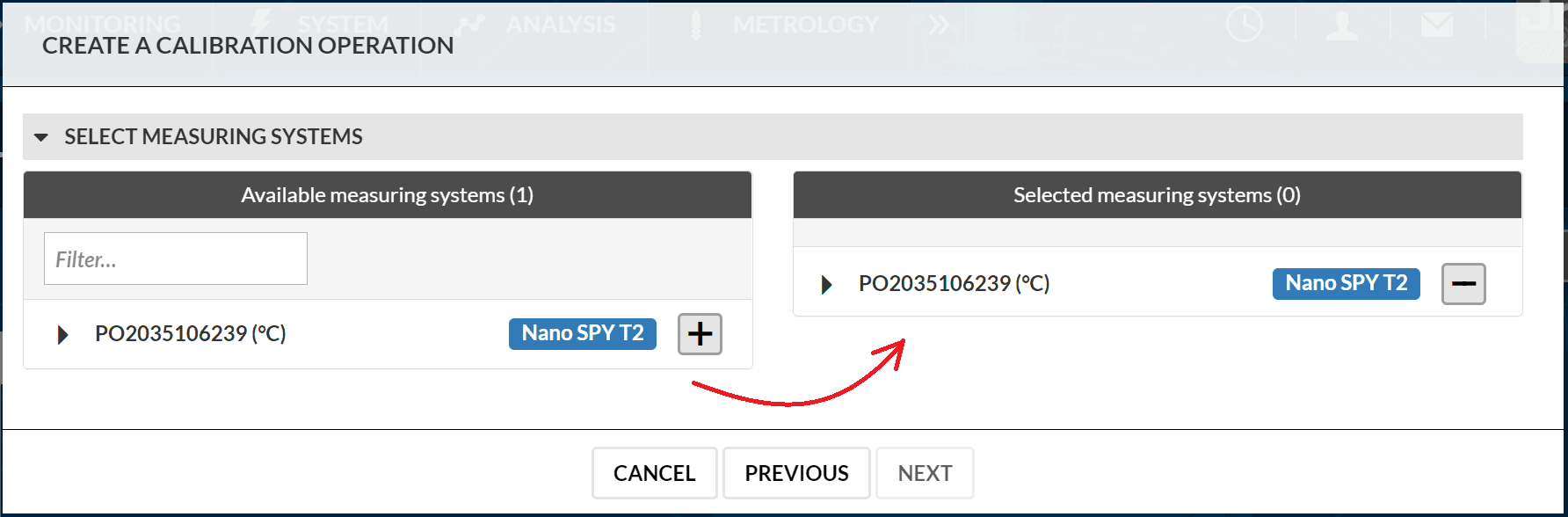

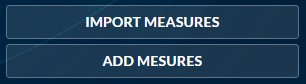

Since MySirius version 4.1, it is possible for the level 2 of the calibration module to perform metrological operations on generic measuring chains. The measurements must be imported into MySirius via a CSV file or entered manually.

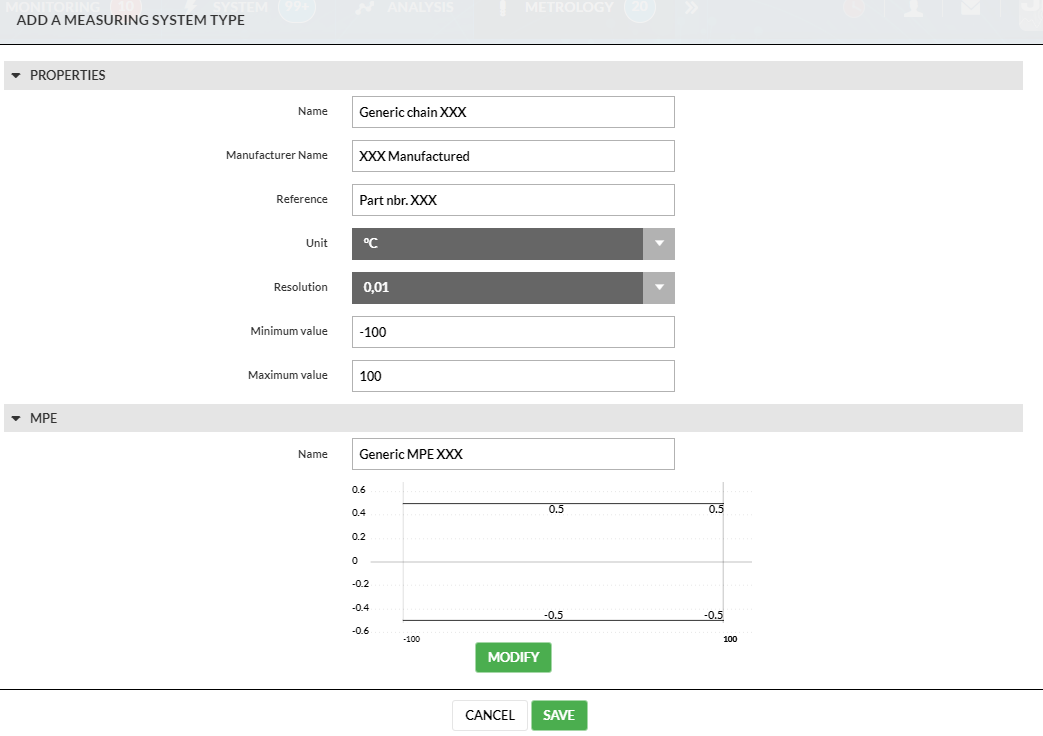

1- Click on add to create a new type or select an existing type to modify or archive it.

2- Fill in the various fields and click on SAVE

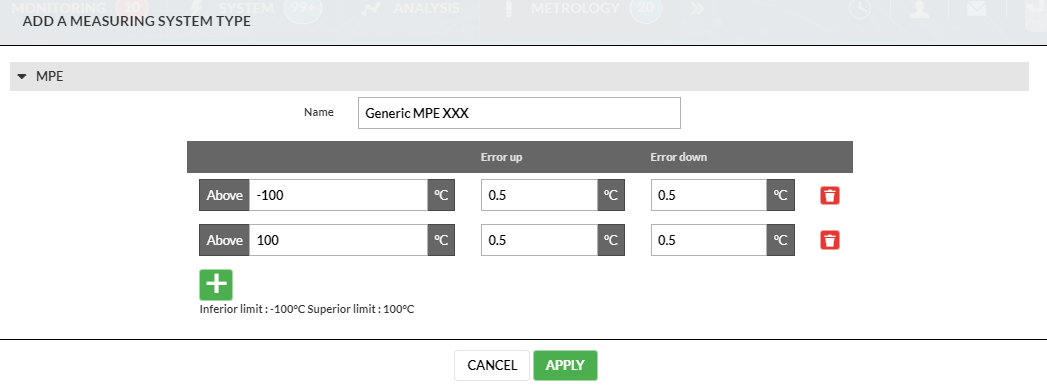

3- The MPE can be modified by clicking on the MODIFY button then SAVE

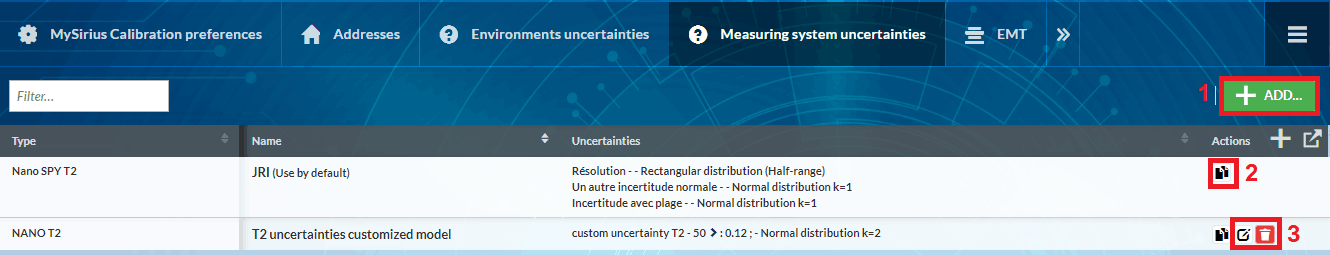

Uncertainty components (Environment and measurement chains)

- Create your uncertainty models by clicking on the ADD button.

- The uncertainty models used by default can be customized. Use the COPY button in ACTIONS to create a new model from existing ones.

- Edit or delete the created models.

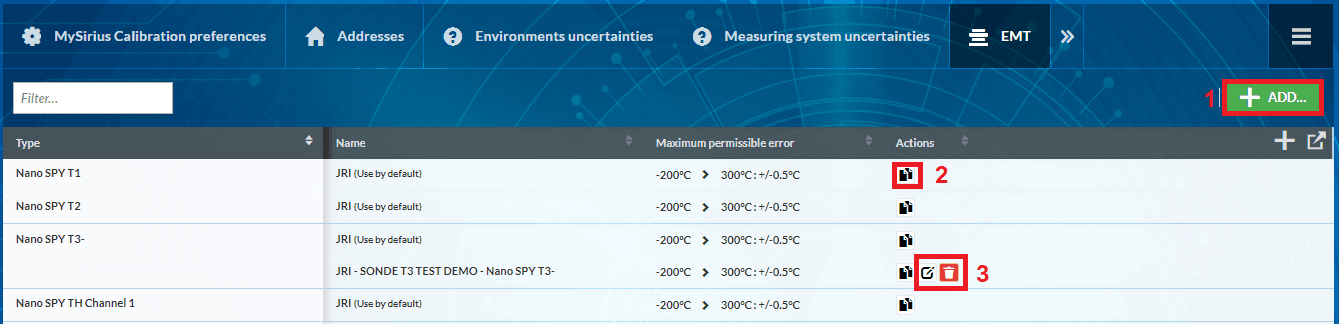

MPE (Maximum Permissible Error / EMT in french)

- Create your MPE models by clicking on the ADD button.

- Default JRI MPE models can be customized (Level 2). Use the COPY button in ACTIONS to create a new template from existing templates.

- Edit or delete the created MPE.

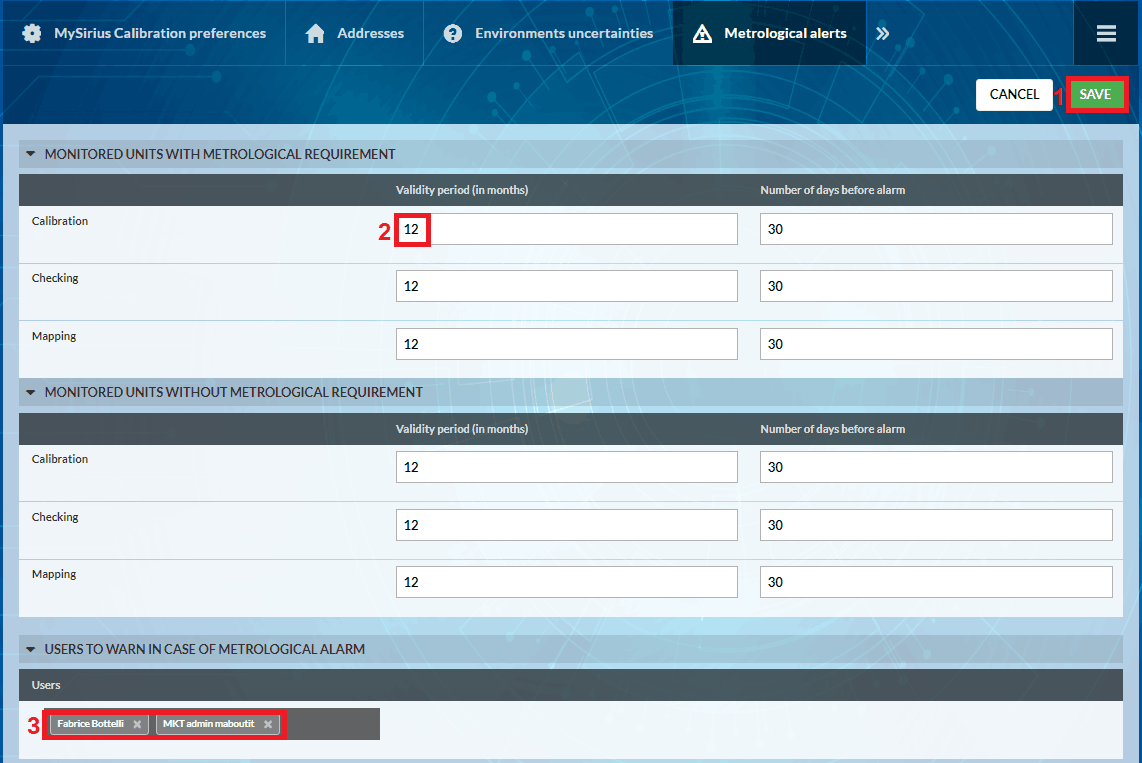

Metrological alerts

Set reminders to anticipate your metrological operations before the end of validity of your certificates. Click on the MODIFY button

- Use the SAVE button to save your changes.

- Enter the desired values in the fields “Validity period” and “Number of days before alarm”.

- Select the users to be notified in case of a metrological alert

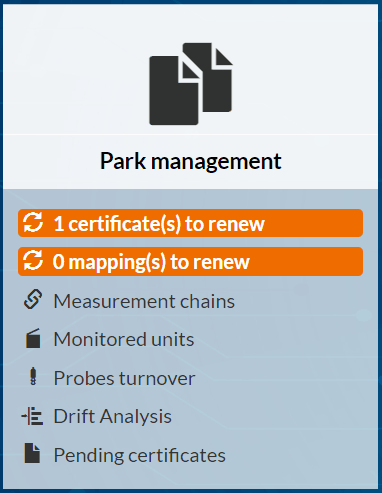

Park (fleet) management

Indicators of metrological operations to be renewed (certificates/maps) allow you to identify the metrological actions to do in priority.

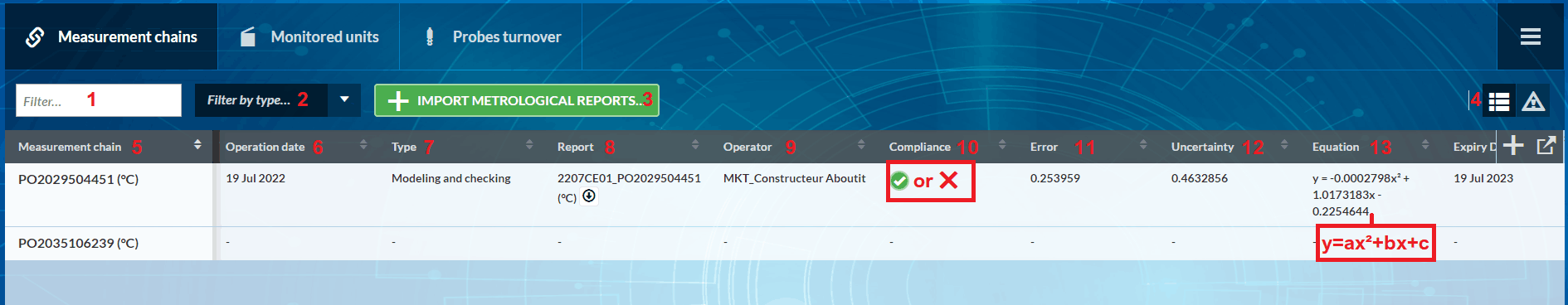

Measurement chains

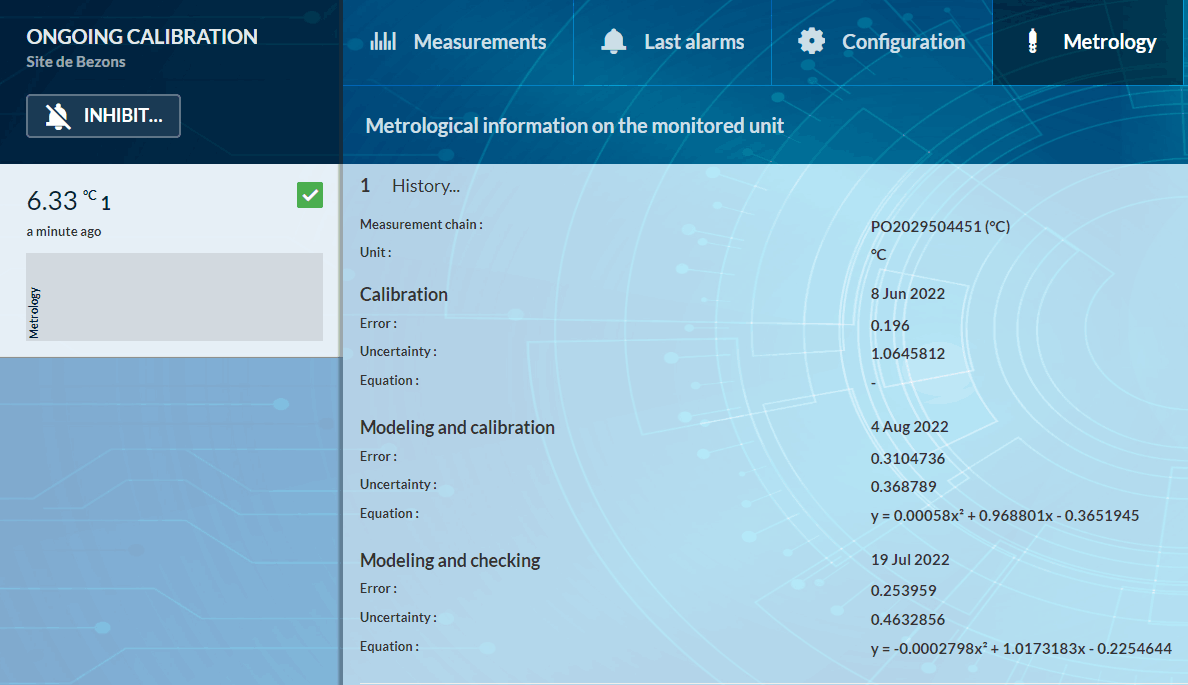

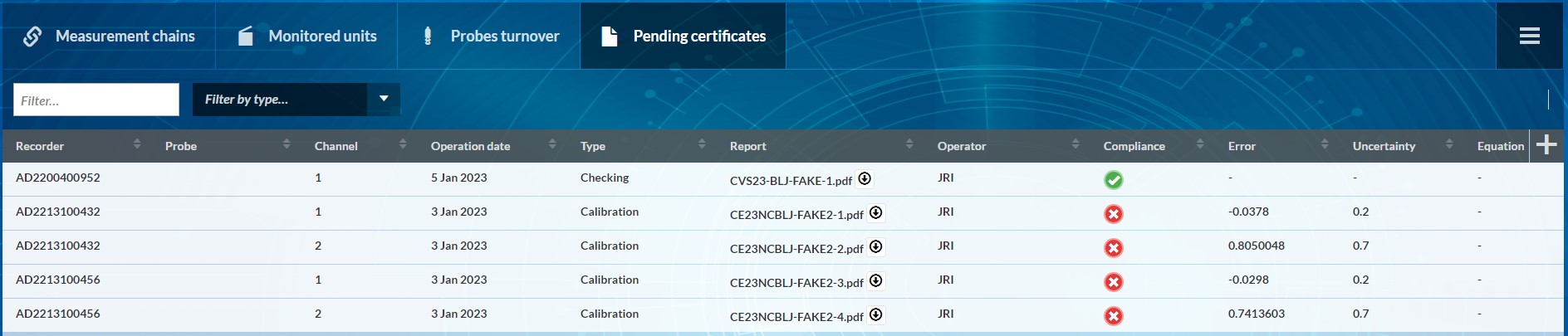

In this screen, you will find all the metrological information related to a measurement chain (device + sensor).

- Search fields by serial number

- Filter by type of operation: Calibration, verification, with or without modelization…

- Import metrological reports: Possibility to import JRI metrological reports by using a drag/drop of files from your computer

- Filter by compliant/non-compliant chains

- Serial number of the measurement chain

- Date of metrological operation

- Type of metrological operation: Calibration, verification, with or without modelization…

- Metrological certificate name: downloadable by clicking on the button ⬇️

- Name of the operator who performed the metrological operation

- Conformity (compliance): can be modified by clicking on it

- Error: Deviation from the standard

- Uncertainty: Sum of the uncertainty components

- Error modelization equation: Correction coefficients a, b, c

- Expiry date of the certificate

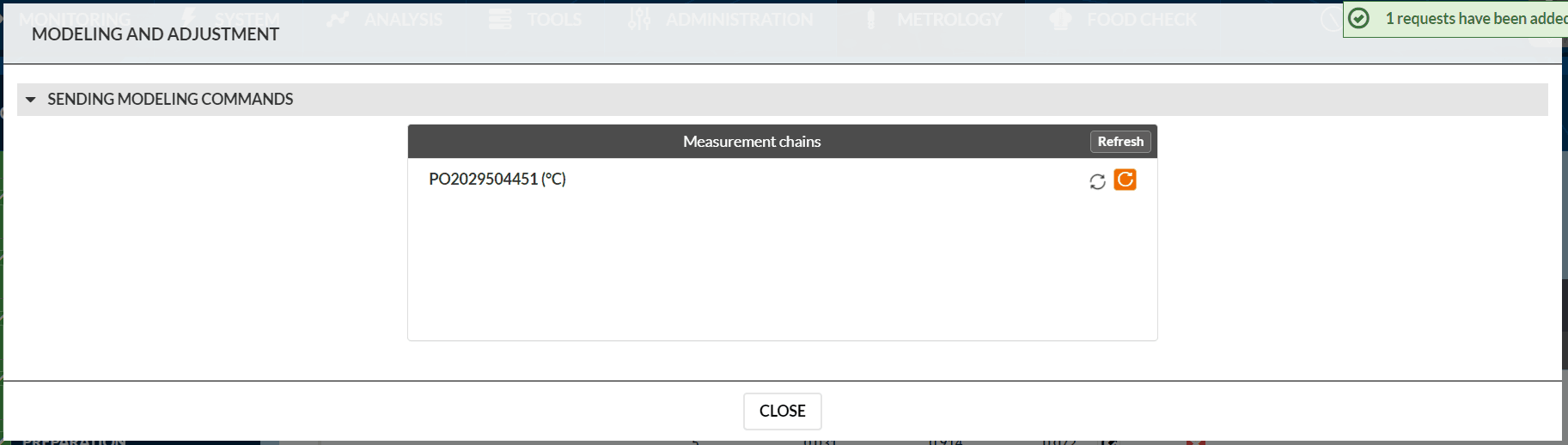

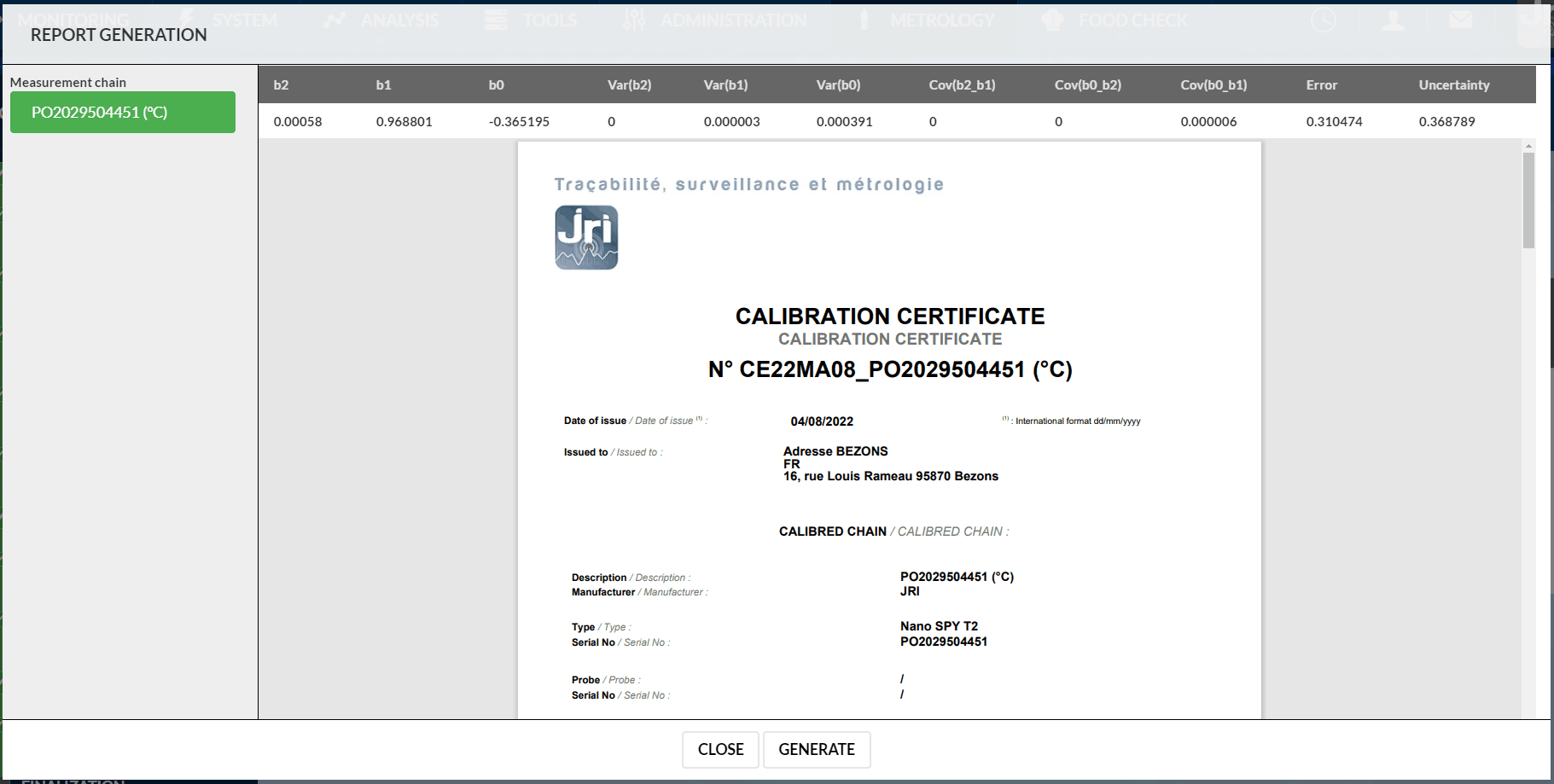

Modelization application

When importing (manually or automatically) new COFRAC calibration certificates or verificationreports made by JRI with an error modelization, you can choose whether or not to apply this modelization in order to adjust your measuring chains.

Following a drag’n’drop: Select a measurement chain and click on “SEND”.

Following automatic addition: In the measurement chain list, a button opens a window. Select the measurement chain and click on “SEND”.

In both cases, once the modelization has been sent, an adjustment is made on the measuring chains based on the correction parameters of the certificate.

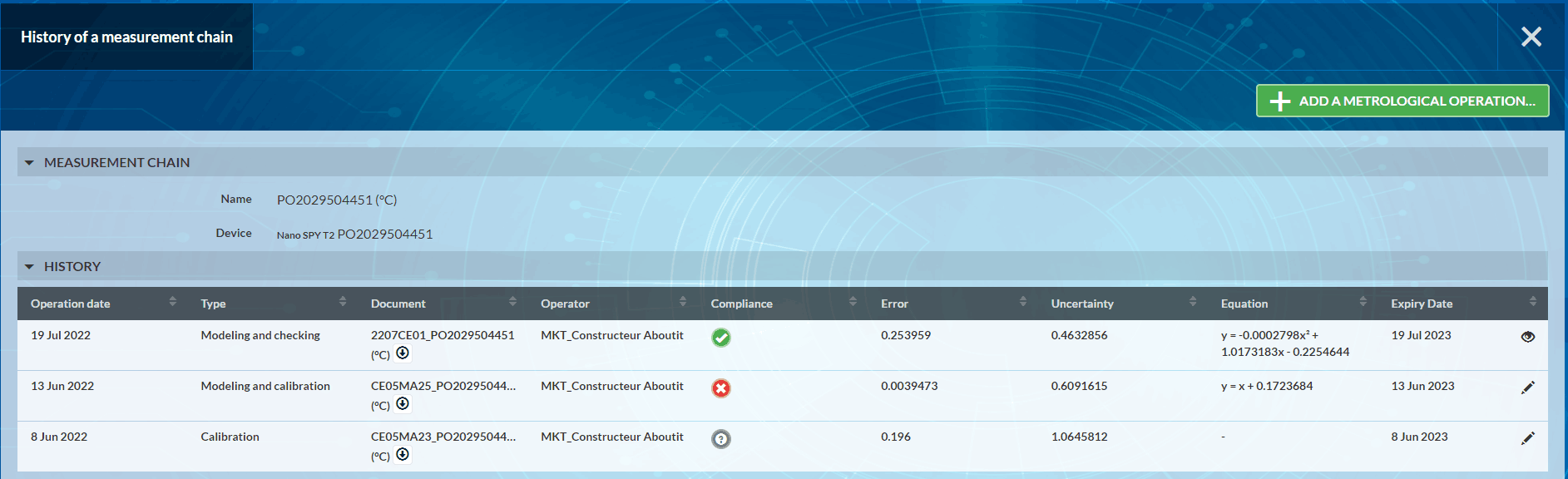

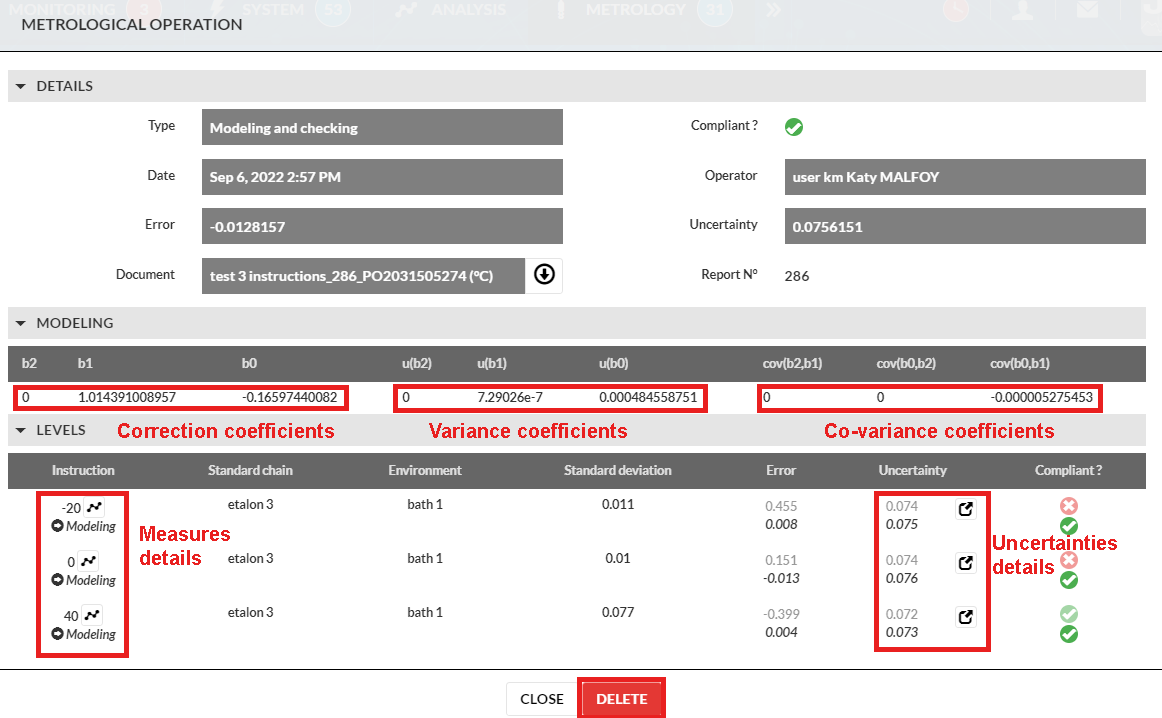

Click on the button 👁️ to :

- see DETAILS of the metrological operation (Type, date, error, uncertainty, conformity, document, operator)

- see MODELIZATION: Correction coefficients, variance, and co-variance

- see LEVELS: The measurements used, as well as the results obtained (Standard deviation, error and uncertainties)

- DELETE: Metrological operations can be deleted, but only if the profile has “Delete a metrological operation” rights. The delete button leads to a screen where a reason must be entered. It is not possible to delete a metrological operation which has sent a command to the device in question, or if the device is a labguard (error message top right).

Monitored units

See details in Administation Guide in Metrology tasks to renew

Probe rotation

See details in Administation Guide in Metrology tasks to renew

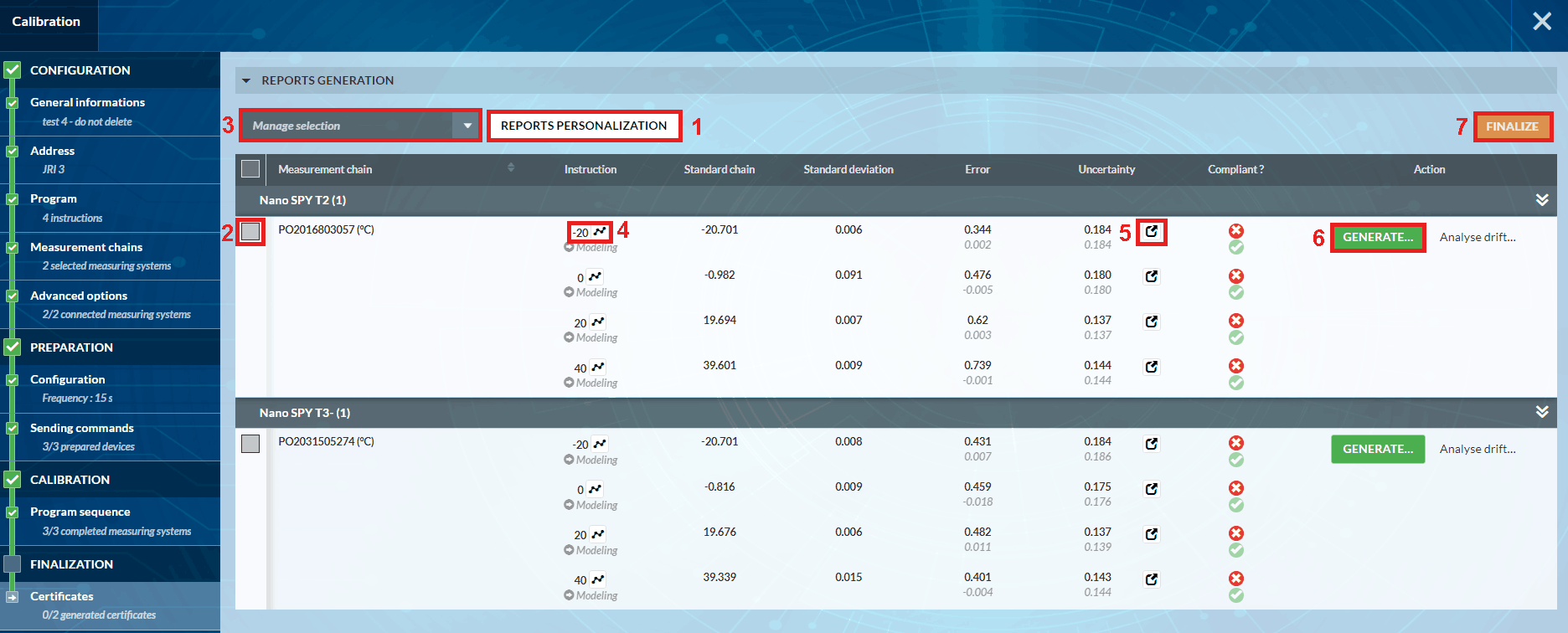

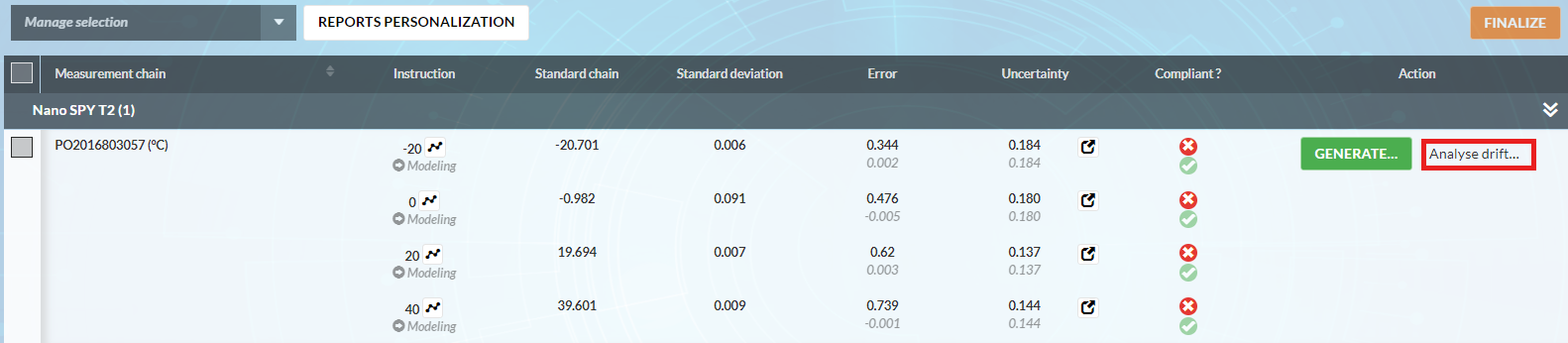

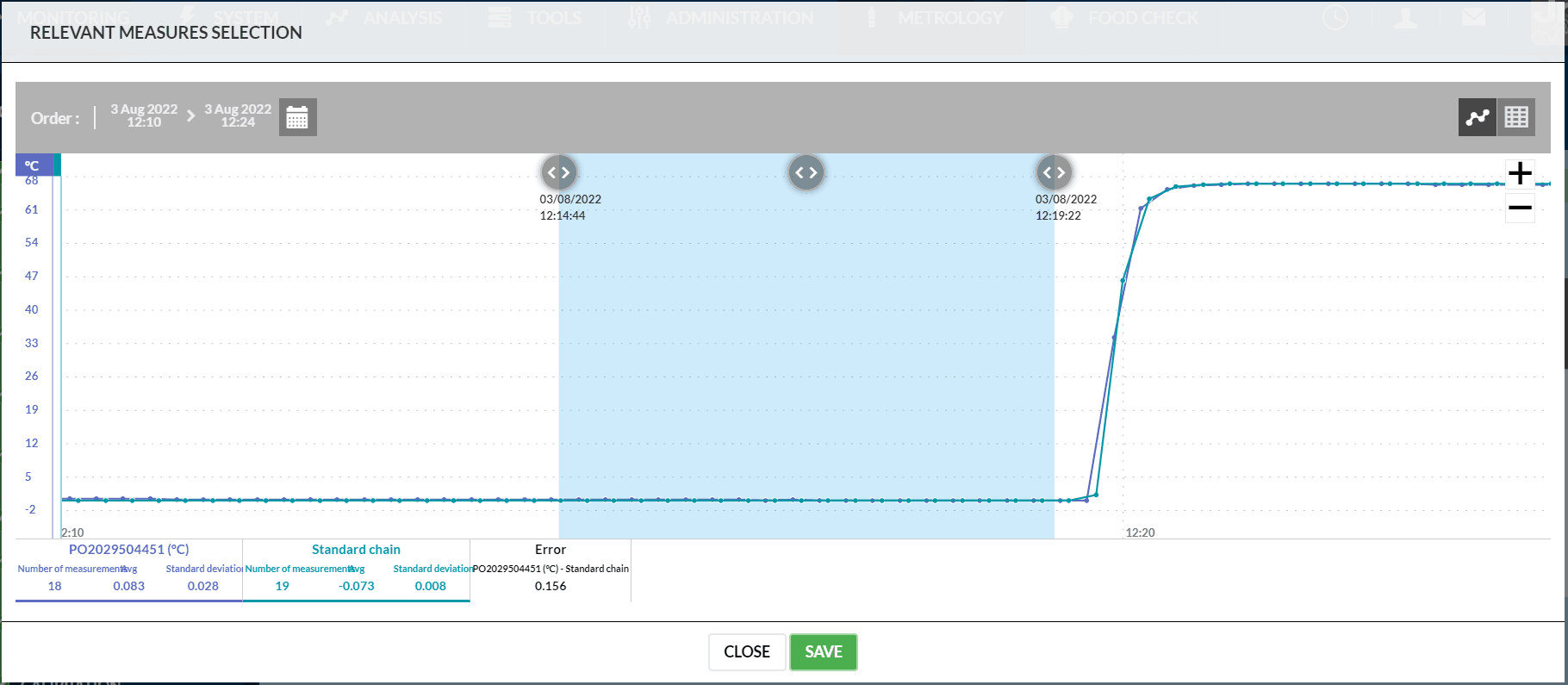

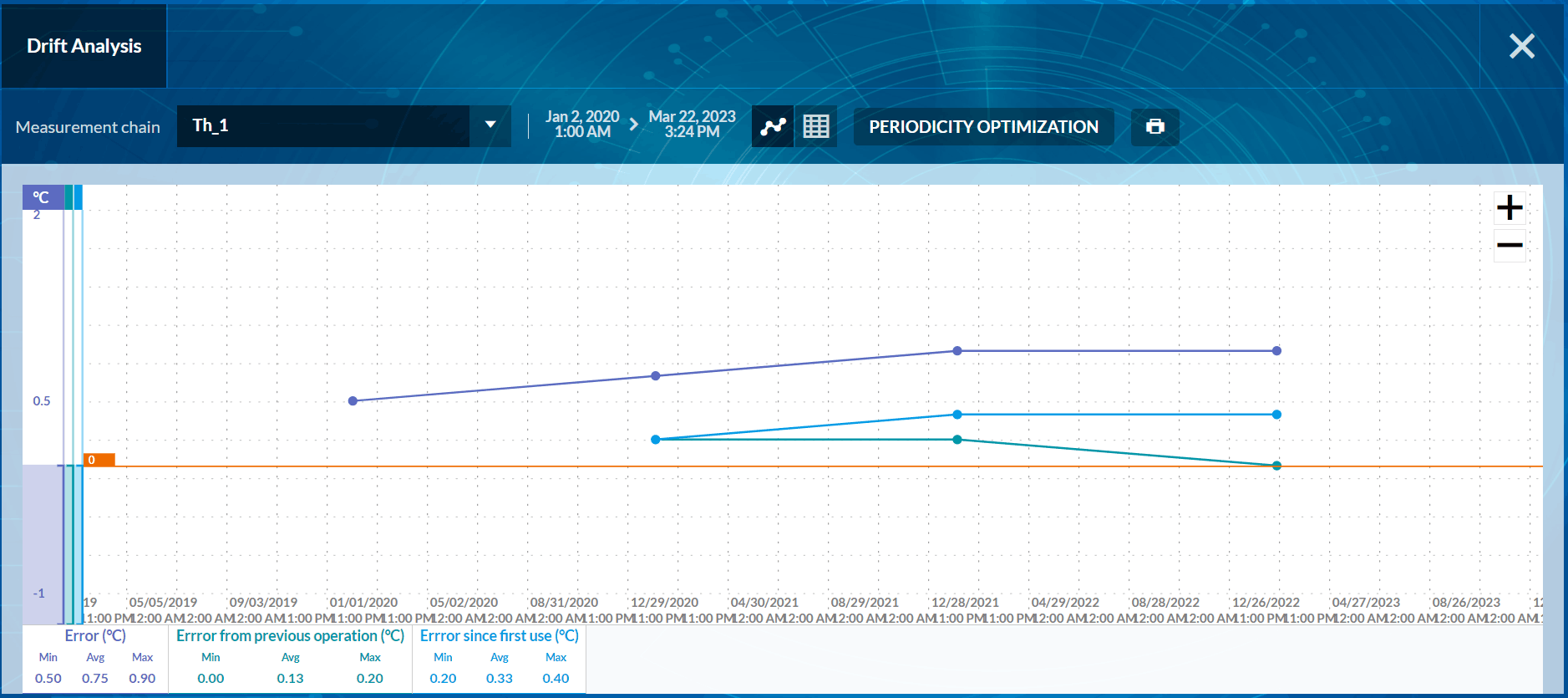

Drift analysis

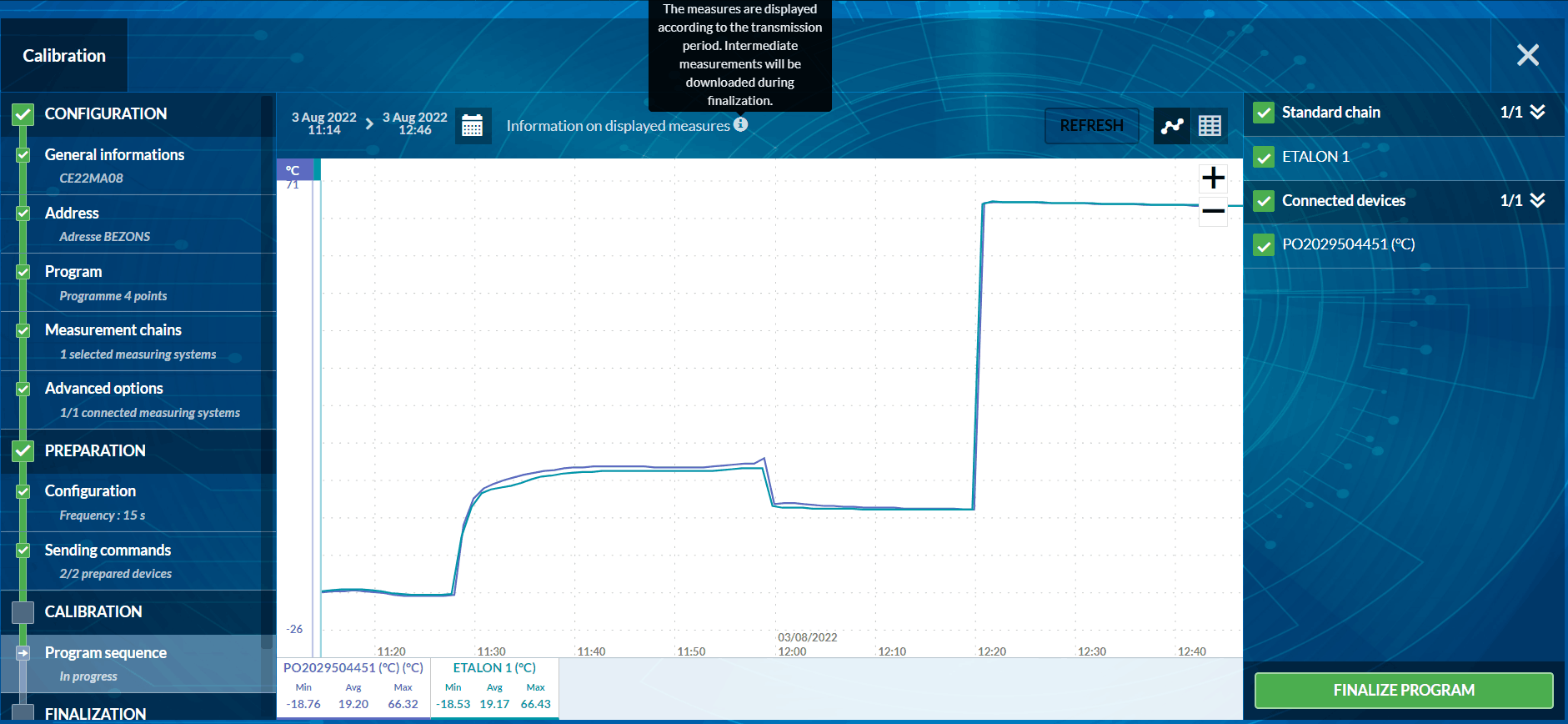

Selection of the measurement chain:

Choose a measuring chain in the list to start the drift analysis on a specified period. The following graph or table is displayed: - Error of each operation with respect to the standard - Error in relation to the previous calibration (drift) - Error in relation to the first use.

It is possible to print the graph or to switch to table display.

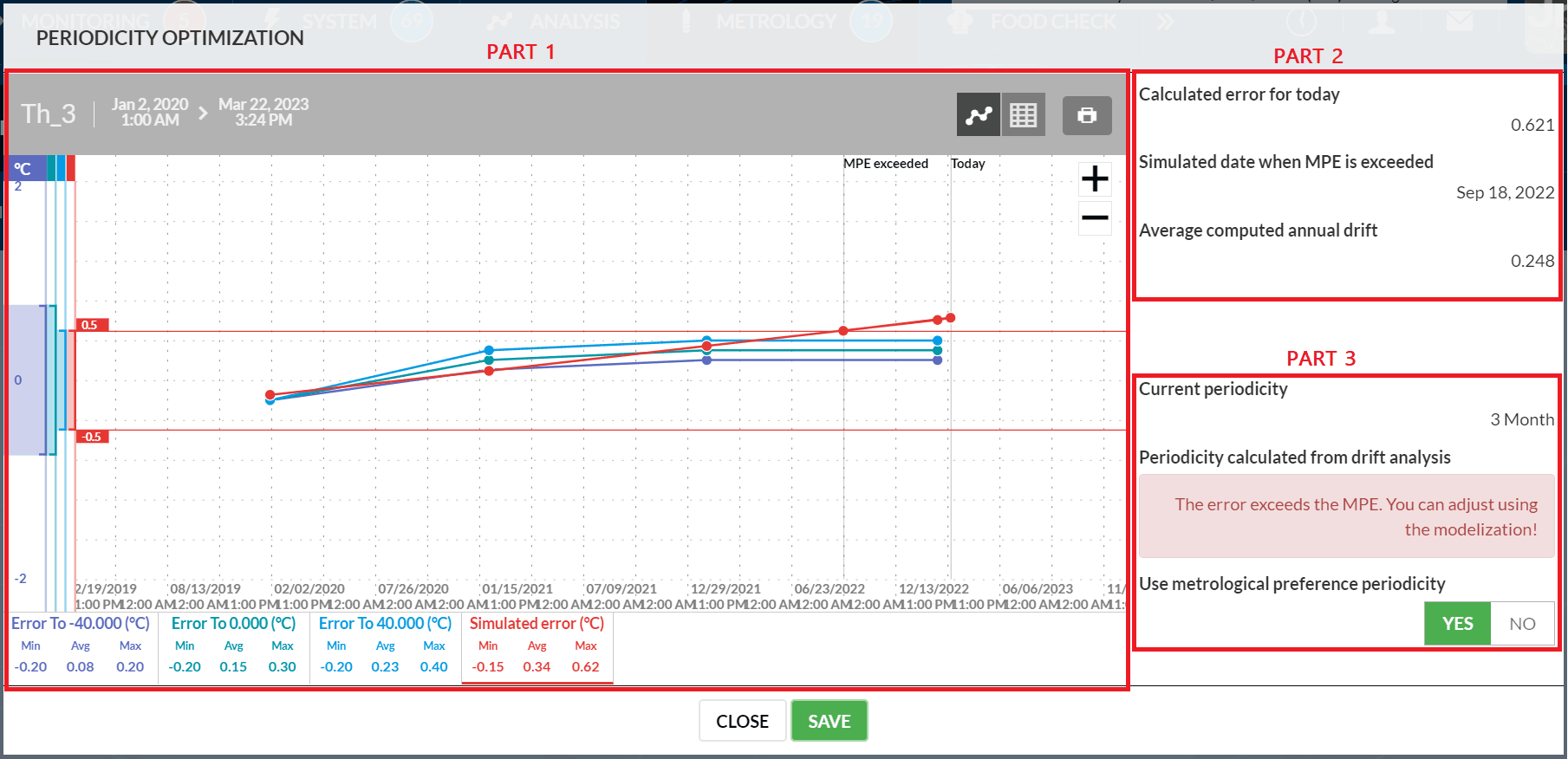

Periodicity Optimization

This feature allows to estimate when an adjustment (by modelling) will be necessary on a chain (If error >or< predefined MPE). This estimation is possible thanks to the drift analysis.

- Part 1: Errors Summary

The following elements are displayed:

- The name of the measurement chain and the period of the drift analysis

- The error graph for each calibration point (here -40°, 0° and +40° C)

- The simulated error graph obtained using the least squares method (in red)

- The MPEs in the form of thresholds which are displayed by clicking on each point (here +/- 0.5°C)

- Part 2: Estimation of the drift

- The simulated error today

- The expected date of exceedance of the MPE

- The calculated annual average drift

- Part 3: Periodicity management

- The current periodicity calculated according to the last operation performed (calibration or verification)

- The periodicity deduced from the drift analysis with an invitation to perform an adjustment if the calibration error exceeds the MPE.

- The choice of whether or not to apply the new periodicity: At the end of the defined time (minus the number of days defined in the metrological alarms), the user will receive a metrological alert e-mail. And the oven will be in metrological alarm when the new period is exceeded.

Pending Certificates

MySirius displays all metrological certificates issued by JRI if you order a new digital probe or measurement chain with a metrological certificate done by JRI. Until the equipment is installed and detected by MySirius, the certificates are visible and downloadable from this page. Once the equipment is installed, the associated certificates are displayed in the “measurement chains” page or in the metrological details of the monitored unit.

Equipment & Programs

This section allows you to declare standards and environments and to use them to create single or multi-point calibration programs.

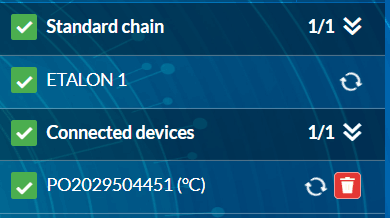

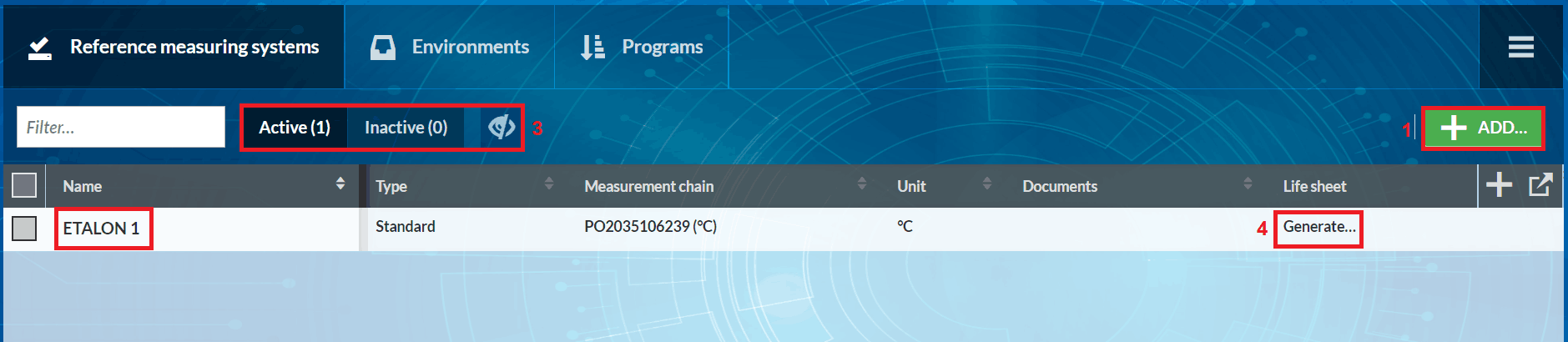

Standards (reference measuring chains)

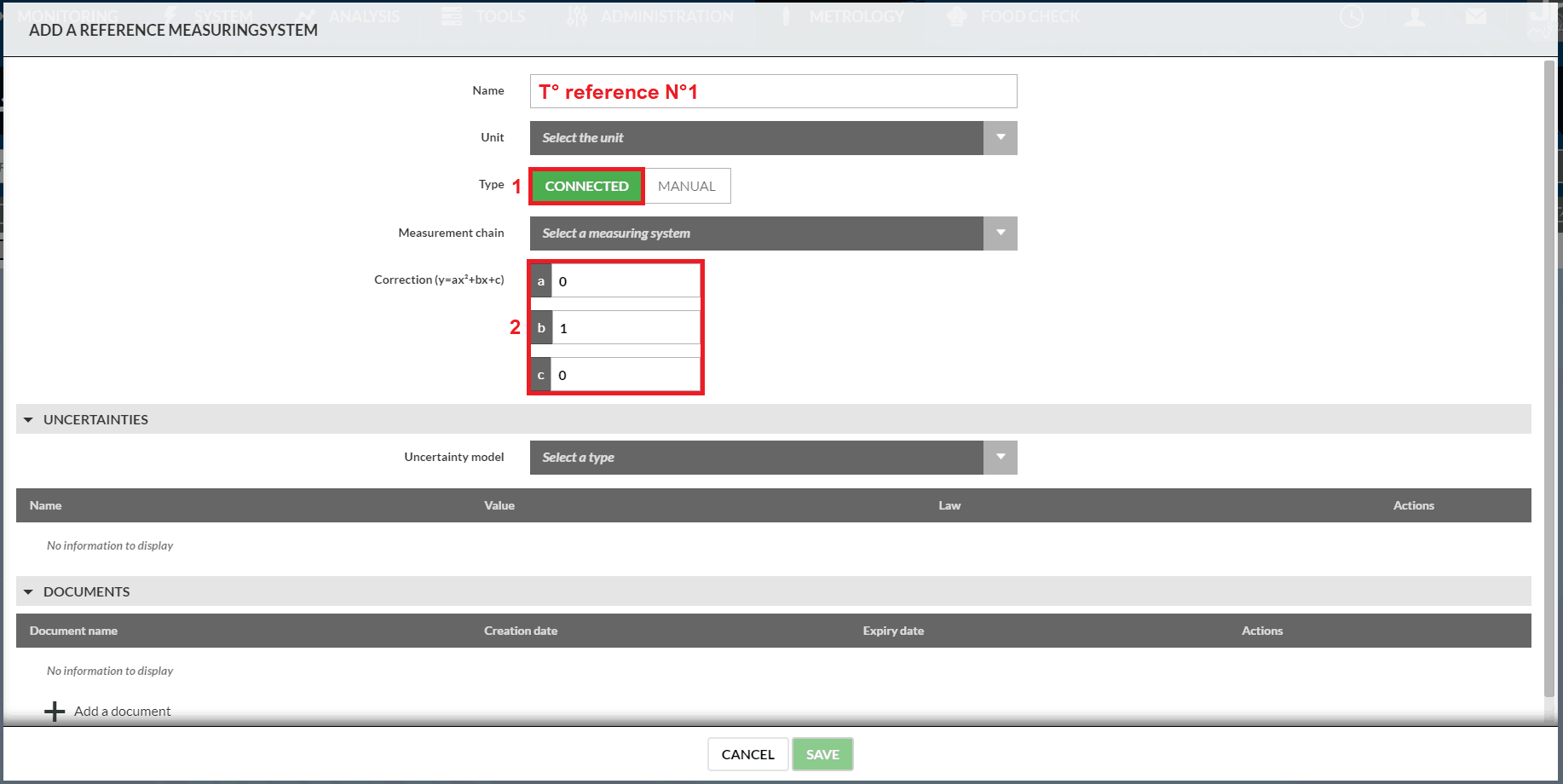

- Create a new standard chain by clicking on the ADD button.

Select the CONNECTED type for the NOVA SPY, NANO SPY and LORA SPY standard chains then choose the corresponding serial number in the field “Measurement chain”.

Select the MANNUAL type to declare a generic standard (except NOVA SPY, NANO SPY and LORA SPY range). It is imperative to declare the measurement chain to be used to display it in the list of measurement chains. Otherwise, use the button “Add a generic measurement chain” to create a new one. It is necessary to select type of chain CUSTOM.

Refer to the calibration certificate of your standard to enter the correction coefficients a,b,c if necessary. If there’s no correction of the read value, put a=0,b=1,c=0

Complete the rest of the form (choice of uncertainty model + add document) and click on SAVE

- Once the standard chain is added to the list, it can be modified by clicking on it.

- Select a standard chain to hide (disable) it using the

. A new selection and then a click on

. A new selection and then a click on  allows a standard to be reactivated.

allows a standard to be reactivated. - Generate a life sheet for each standard. Each time a modification is made, the life sheet is updated.

Calibration environments

Declare your calibration baths, ovens and climatic or thermostatic chambers used to perform your calibrations.

Same operating principle as for adding a standard (Add, click on the name to modify, select to activate/deactivate)

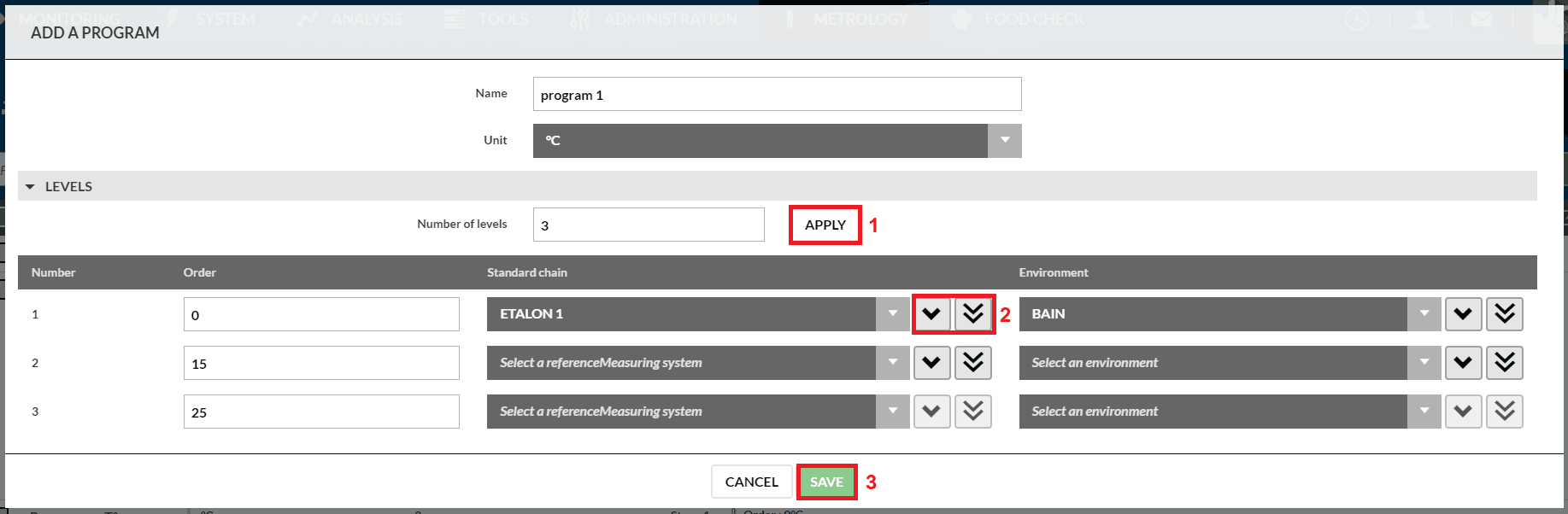

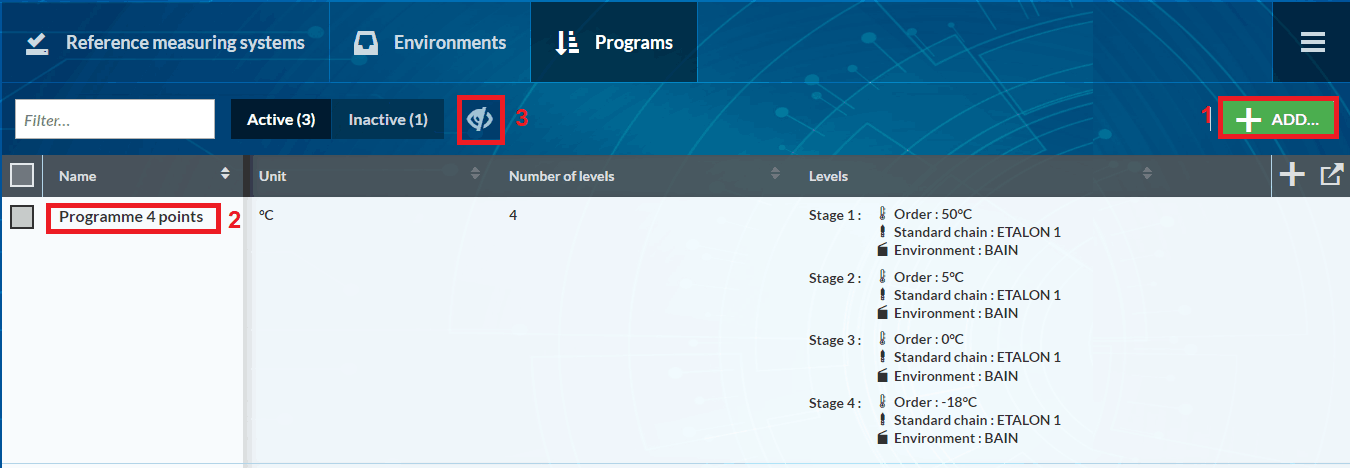

Programs

Once the standard chains and environments have been added, they can be combined to create single (Level1) or multi-point (Level 2) calibration programs (minimum 4 for modelization)

- Create a new program using the ADD button

- Enter the correct number of LEVELS (calibration points) and click on APPLY.

- Enter a standard chain and a calibration environment for each level.

- The arrows can be used to apply the selected items used from one level to another or select them for all levels.

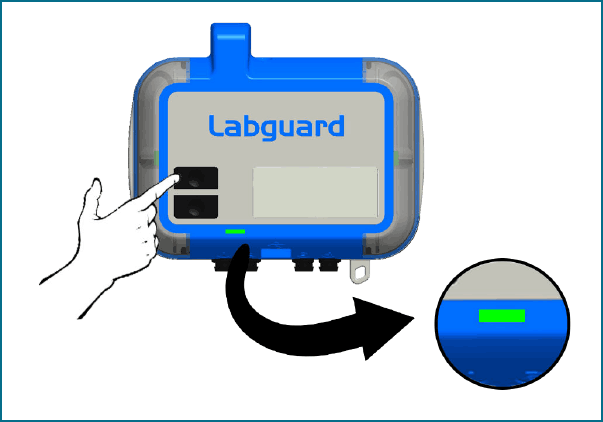

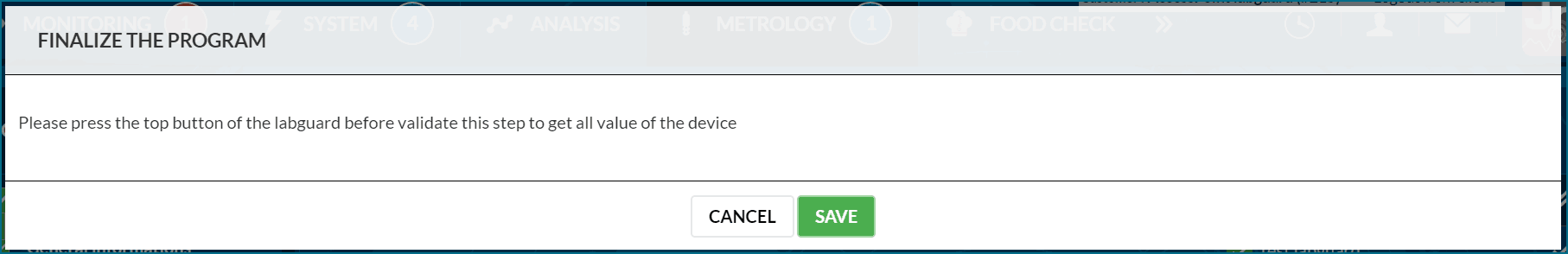

- Click on SAVE